Hõbenool uses special automatic transmission maintenance and repair equipment in its work. We give you a brief overview, starting with a more complex one and moving towards a simpler one.

Testing of hydraulic blocks

A hydraulic block is a transmissions control unit, which is usually located at the bottom of the transmission. It consists of an aluminum casing, springs, high precision valves and solenoids. It is undoubtedly the most sophisticated detail in the automatic transmission. Less wear in the valves or housing will cause malfunctions in the transmission.

Special test stands are used for testing. At the moment, the Hõbenool has currently the latest generation of devices on the market, exceeding the equipment available in neighboring countries in terms of their technical level. It is a device made by PowerTrain Labs (formerly FluidLogic) in England and is run by the most up-to-date control system from BlueReach.

Repair of the control units

Currently, the best available tool selection for the United States is Sonnax. These are high-precision mills that drill the worn control unit a bit larger and a new valve is installed. That is a so-called locksmith’s work.

Repair of the torque converters

A hydraulic coupling is a clutch between the engine of the vehicle and the transmission. It is a closed item that the ordinary businesses can not open. There are 4-5 device manufacturers in the world, whose tools can be used to repair hydraulic connections. If the lathe with which the hydraulic coupling is cut can still be found in each well-equipped store, the sintering of the clutch discs and the welding device of the turbine housing are special aggregates.

In the most complex processes Hõbenool uses the devices of the US company SuperFlow. The same series of devices can also be found in neighboring countries and elsewhere in Europe.

Dynamic oil change

For a dynamic oil change, we use a device that has been created by Tim Eckart Automatikölwechselsystem Manufaktur, the world’s first and so far the best manufacturer of equipment in our opinion.

The device enables maintenance on both planetary, CVT and DSG transmission. According to the operating principle of this device, virtually all other machine manufacturers’ machines have been manufactured (currently about ten manufacturers). The main difference lies in the packaging – whether the device is packed in a shiny plastic body or not. In addition to the plastic body, the oil bath has been lost, which has the only possibility to blow through the hydraulic unit of the transmission, the cooling system and the lubrication unit of the transmission.

The advantage of this device is the excellent universality, where the entire process is controlled by the operator. This allows you to change both the input and output process. It is also the biggest drawback – the device requires strong training, where each transmission needs to be operated differently. A great operator gets a VEY good result with this device, while mediocre does not. The equipment of other equipment manufacturers available on the market can provide a mediocre result, but does not require special skills.

We have modified this device and installed a more powerful pump with a control system to speed up the process and carry out a heavier load (cleaner transmission). We have also modified the adapters to increase their flow rate.

Hõbenool has a total of 6 devices.

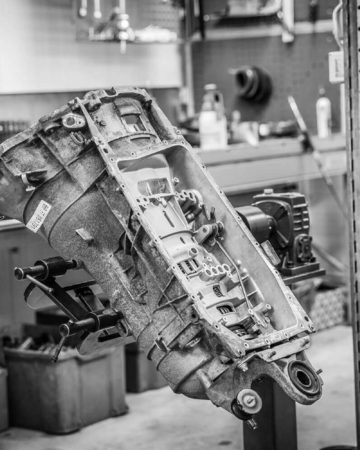

The repair of the mechanics of the transmission

The repair of the transmission mechanic’s part works exactly the same way around the world. The transmission is disassembled, cleaned, checked for knots and replaced with cost components, after which the box is assembled. Purity and accurate measurement are important in the process. We use special attachments and workbenches for the disassembly and assembly of transmission, as well as cleaning cups and measuring devices for axial and radial evaluation, and for measuring internal leakage of the transmission.